Coagulation? Flocculation? Coagulation aid? Among water treatment agents, coagulation and flocculation, polyaluminium chloride and polyacrylamide are the most widely used. So what are the specific precautions in the use of the two? Let Wilp take you to explore the environment.

Coagulation: When coagulant is added, the colloid in water loses its stability, and colloid particles coagulate with each other, resulting in numerous "little alum flowers".

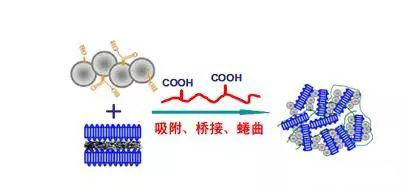

Flocculation: The process of flocculation in which the "little alum flower" formed in the process of coagulation forms larger particles through adsorption, banding and bridging.

Coagulation: It is the general name of the two processes of coagulation and flocculation. It is the aggregation process of colloidal particles and micro-suspended particles in water.

That is to say, "coagulation" includes the whole process from raw water dosing to water mixing, drug reaction (destabilization, flocculation) to the formation of large particles of flocculants. Flocculation refers to the stage when the colloidal particles destabilize and form large flocs from small flocs. Therefore, flocculation is only one step of coagulation!

So what are polyaluminium chloride and polyacrylamide?

Polyaluminium chloride (PAC)

Colloids in sewage or sludge can be precipitated quickly through it or its hydrolysate, which is easy to separate large particles. The molecular formula of PAC is [AL2 (OH) nCl6-n] m, where n is any integer of 1-5, m is the degree of polymerization, that is, the number of links, m is not more than 10.

The coagulation effect of PAC is closely related to the ratio of OH to AL L (n value), which is usually expressed by alkalinity B=[OH]/(3[AL]) X100%. B requires 40-60%, the suitable PH range is 5-9.

Polyacrylamide (PAM)

Commonly known as flocculant or coagulant, belongs to coagulant. The average molecular weight of PAM ranges from tens of millions to tens of millions. There are several functional groups along the bond molecule. Most of them are ionized in water and belong to polymer electrolyte. It can be divided into anionic polyacrylamide, cationic polyacrylamide and nonionic polyacrylamide according to the characteristics of its dissociatable groups.

PAM is white powder, soluble in water, almost insoluble in benzene, ether, esters, acetone and other general organic solvents, polyacrylamide aqueous solution is almost transparent viscous liquid, non-hazardous, non-toxic, non-corrosive, solid PAM has hygroscopicity, hygroscopicity increases with the increase of ionicity, thermal stability of PAM is good; heated to 100 ~C, but above 150 ~C, the stability of PAM is good. Nitrogen is easily decomposed to produce medium nitrogen, which is imidized between molecules but insoluble in water. The density is 1.302 mg/l (23 C). The glass transition temperature of PAM is 153 C, and PAM exhibits non-Newtonian fluidity under stress.

Cationic and anionic PAM are suitable for sewage or sludge with negative and positive charges respectively. The activated sludge produced by biochemical method has negative charge and should be cationic. Anionic PAM can be used to treat wastewater or sludge with positive charge, such as iron and steel plant, electroplating plant, metallurgy, coal washing and dust removal. Non-ionic has good effect on cations and anions, but the unit price is very expensive, which increases the cost of treatment. In addition, it is the reaction conditions and dosing requirements of the two.

Actual dosage of flocculant:

1. The Function of Flocculation Pool

The function of the flocculation tank is to make the coagulant fully mix with the water after it is added into the raw water. Most colloidal impurities in the water lose their stability. The destabilized colloidal particles collide and coagulate with each other in the flocculation tank, and finally form flocs which can be removed by precipitation method.

2. Reaction Conditions

Floc growth is a process of contact and collision of micro-particles. The effect of flocculation depends on two factors: one is the ability of polymer complexes formed by hydrolysis of coagulants to form adsorption bridging, which is determined by the properties of coagulants; the other is the probability of collision of micro-particles and how to control them to collide reasonably and effectively.

Water treatment engineering disciplines believe that in order to increase the probability of collision, it is necessary to increase the velocity gradient, and to increase the velocity gradient, it is necessary to increase the energy consumption of the water body, that is, to increase the flow rate of the flocculator. On the one hand, if the particles coagulate too fast in the flocculation, there will be two problems:

(1) The strength of flocs decreases when they grow too fast. When they meet strong shear in the flow process, the adsorption bridging will be cut off. It is difficult to continue the adsorption bridging when they are cut off. Therefore, the flocculation process is also a speed-limited process. With the growth of flocs, the flow velocity should be reduced continuously, so that the formed flocs are not easy to be broken.

(2) The specific surface area of flocs in water decreases sharply due to the rapid growth of some flocs, and some small particles with imperfect reactions lose their reaction conditions. The collision probability between these small particles and large particles decreases sharply and it is difficult for them to grow up again. These particles can not be intercepted not only by sedimentation tanks, but also by filters.

3. Addition Requirements

In the early stage of reaction with coagulant, it is necessary to increase the chance of contact between the agent and sewage as much as possible, and increase the agitation or flow rate. Depending on the collision of water flow with folded plates and the multiple turning of water flow between folded plates, the collision opportunity of particles in water is increased and flocs are agglomerated. At the later stage of the reaction, in order to reduce the velocity gradient, better flocculation and precipitation effects can be obtained.

Look at the following minor issues:

Q: Why can't there be many small impurities in the water?

A: When the size of suspended particles in water is small enough, the energy of Brownian motion is enough to prevent the action of gravity, so that the particles do not subside. The suspension can remain stable for a long time. Moreover, the surface of suspended particles is often charged (often negative), and the repulsion of the same charge between particles makes it difficult for particles to merge and enlarge, thus increasing the stability of suspension.

Q: In principle, what is the difference between coagulation and flocculation?

A: The process of coagulation is to neutralize the negative charge on the surface of particles by adding a positive coagulant on the surface so as to destabilize them. Flocculation is a process in which polymer chains bridge suspended particulate matter and aggregate particulate matter. Therefore, most coagulants are water-soluble polymers with low molecular weight and high positive charge density, while flocculants are generally polymers with specific electrical properties and charge density.

Having talked so much, do you feel dizzy? In fact, it is estimated that many friends have found that the difference between the two is not clearly defined, that is, a little different but not clearly demarcated, in fact, the two have a high degree of coincidence in use. So it's normal to be confused...

Should we say coagulation or flocculation?

When it comes to technology, let's talk about coagulation! Because the concept of coagulation is big, it must be right! When it comes to operation, flocculation can be said, such as "flocculation effect is good, floc is very big", "flocculation effect is not good, try another flocculant" and so on.

In fact, the definitions of coagulants and flocculants are also varied. Basically, the commonly used aluminium salts, iron salts and polyacrylamides can be called coagulants or flocculants... As for coagulant aid, some people believe that it is equivalent to flocculant, others think that coagulant aid is PAM...

Copyright © Jiangsu Welpep Environmental Protection Technology Co., Ltd.

Hotline:+86-523-8878-3456

E-mail:sales@welpep.com

Working hours:8:00-17:00

苏ICP备17065064号